I,the hydraulic pump connection precautions

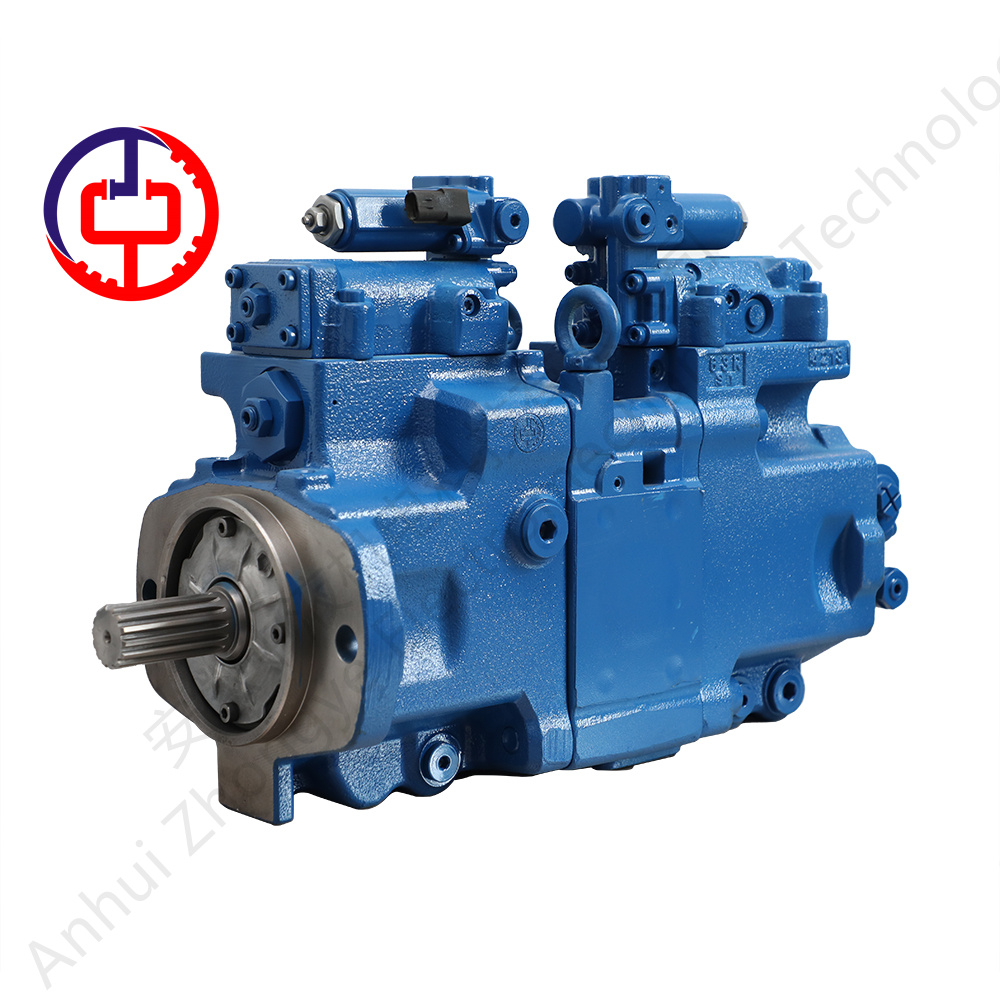

1, the hydraulic pump can be installed with a support or flange, the pump and the prime mover should use a common base support, flange and base should be sufficient rigidity. Special attention: flow greater than (or equal to) 160L/min piston pump, should not be installed on the tank.

2, the hydraulic pump and the prime mover output shaft should be connected by flexible coupling, it is strictly prohibited to install the pulley or gear on the hydraulic pump shaft to drive the hydraulic pump, if you have to use the pulley or gear to connect with the pump, you should add a pair of standoffs to install the pulley or gear, and the coaxiality error between the standoffs and the pump shaft should be no more than Φ0.05mm.

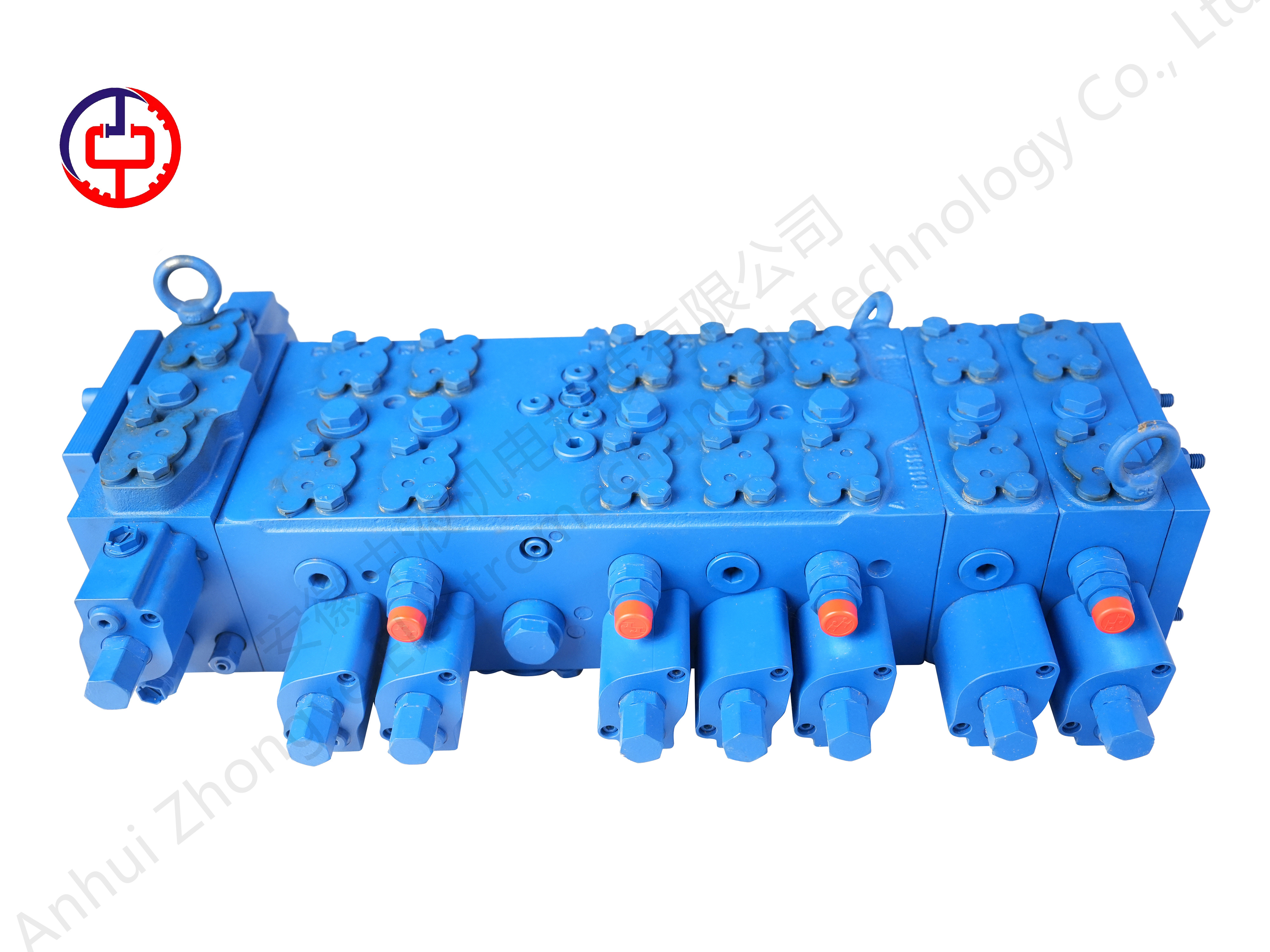

3, the suction pipe should be as short, straight, large and thick as possible, the suction line generally need to set the nominal flow rate is not less than 2 times the pump flow rate of the coarse filter (filtration accuracy is generally 80 ~ 180μm). The drain pipe of the hydraulic pump should be connected directly to the oil tank, and the back pressure of the return oil should be no more than 0.05MPa. The suction pipe port and return pipe port of the oil pump should be below 200mm of the lowest oil level of the oil tank. Special attention in the piston pump suction pipe is not allowed to install oil filters, suction pipeline cut-off valve diameter should be larger than the suction pipeline diameter of one block, suction pipeline length L < 2500mm, pipe elbow not more than two.

4, hydraulic pump inlet and outlet should be installed firmly, the sealing device should be reliable, otherwise it will produce the phenomenon of air intake or oil leakage, affecting the performance of the hydraulic pump.

5, the hydraulic pump self-priming height of not more than 500mm (or the inlet vacuum of not more than 0.03MPa), if the use of oil supply pump oil supply pressure shall not exceed 0.5MPa, when the oil supply pressure of more than 0.5MPa, to be changed to pressure-resistant seals. For the piston pump, should try to use reverse self-priming.

6, the hydraulic pump should be installed before checking the depth of the mounting hole is greater than the length of the pump's shaft extension, to prevent the phenomenon of the top shaft, otherwise the pump will be burned.

II,the use of hydraulic pump precautions

1, the hydraulic pump should be started several times, the direction of oil flow and sound are normal, run at low pressure for 5 ~ 10min, and then put into normal operation. Before starting the piston pump, the pump must be filled with clean working oil through the oil drain port on the shell.

2, the viscosity of the oil is affected by the temperature and changes, the oil temperature increases viscosity decreases, so the oil temperature is required to remain below 60 ℃, in order to enable the hydraulic pump to work stably at different operating temperatures, the selected fluid should have a viscosity affected by the temperature change of the oil temperature characteristics of the smaller, as well as better chemical stability, anti-foam properties. Recommended use of L-HM32 or L-HM46 (GB11118.1-94) anti-wear hydraulic oil.

3, the fluid must be clean, not mixed with mechanical impurities and corrosive substances, suction line without filtering device of the hydraulic system, must be filtered by the oil filter car (filtration accuracy of less than 25μm) refueling to the tank.

4, the maximum pressure and maximum speed of the hydraulic pump, is the peak allowed in the use of a short period of time, should be avoided for a long time, otherwise it will affect the life of the hydraulic pump.

5, the normal operating oil temperature of the hydraulic pump is 15 ~ 65 ℃, the maximum temperature on the pump casing is generally higher than the oil temperature in the tank at the pump inlet 10 ~ 20 ℃, when the oil temperature in the tank reaches 65 ℃, the maximum temperature on the pump casing does not exceed 75 ~ 85 ℃.

Home

Home

Product

Product

Equipment

Equipment

Contact

Contact