The excavator distribution valve, as a key construction machinery in earthwork and stonework projects, is widely used in the fields of construction, road building, water conservancy, open-pit mining, and national defense projects. However, if timely maintenance is not emphasized, it may encounter various faults. Come and understand together!

(1) Insufficient battery power: The battery should be charged in time, and the electrolyte should be checked and replenished to the specified height. If it is found that the battery is aging and has poor charging, it needs to be replaced. At the same time, pay attention to daily maintenance to avoid the battery often being in a state of power loss.

(2) Starter failure: Repair or replace the starter.

(3) Generator failure: Repair or replace the generator.

(4) Circuit fault: Check and repair the circuit.

(1) Low-pressure fuel circuit air resistance: When the fuel injection pump or fuel transfer pump sucks, if the low-pressure fuel circuit is not tightly sealed, the fuel tank oil level is too low, and the vehicle is parked or driven tilted, as well as when the fuel evaporates at high temperatures, air resistance may be formed in the low-pressure fuel circuit, resulting in unstable engine operation, automatic shutdown, or inability to start.

(2) Fuel circuit blockage: It is commonly found in parts such as the suction pipe in the fuel tank, the filter screen, the diesel filter, and the ventilation hole of the fuel tank cover. Mainly due to the injection of non-standard diesel or the mixing of impurities when refueling. The key lies in ensuring the cleanliness of diesel and the sealing of the fuel circuit, strengthening the cleaning and maintenance of the diesel filter, timely cleaning or replacing the filter element, and thoroughly removing the sludge and moisture at the bottom of the fuel tank according to the working environment.

(3) Fuel injection pump failure: Severe wear of the plunger and outlet valve pair of the fuel injection pump will cause difficulty in starting the engine, and it should be replaced in time at this time.

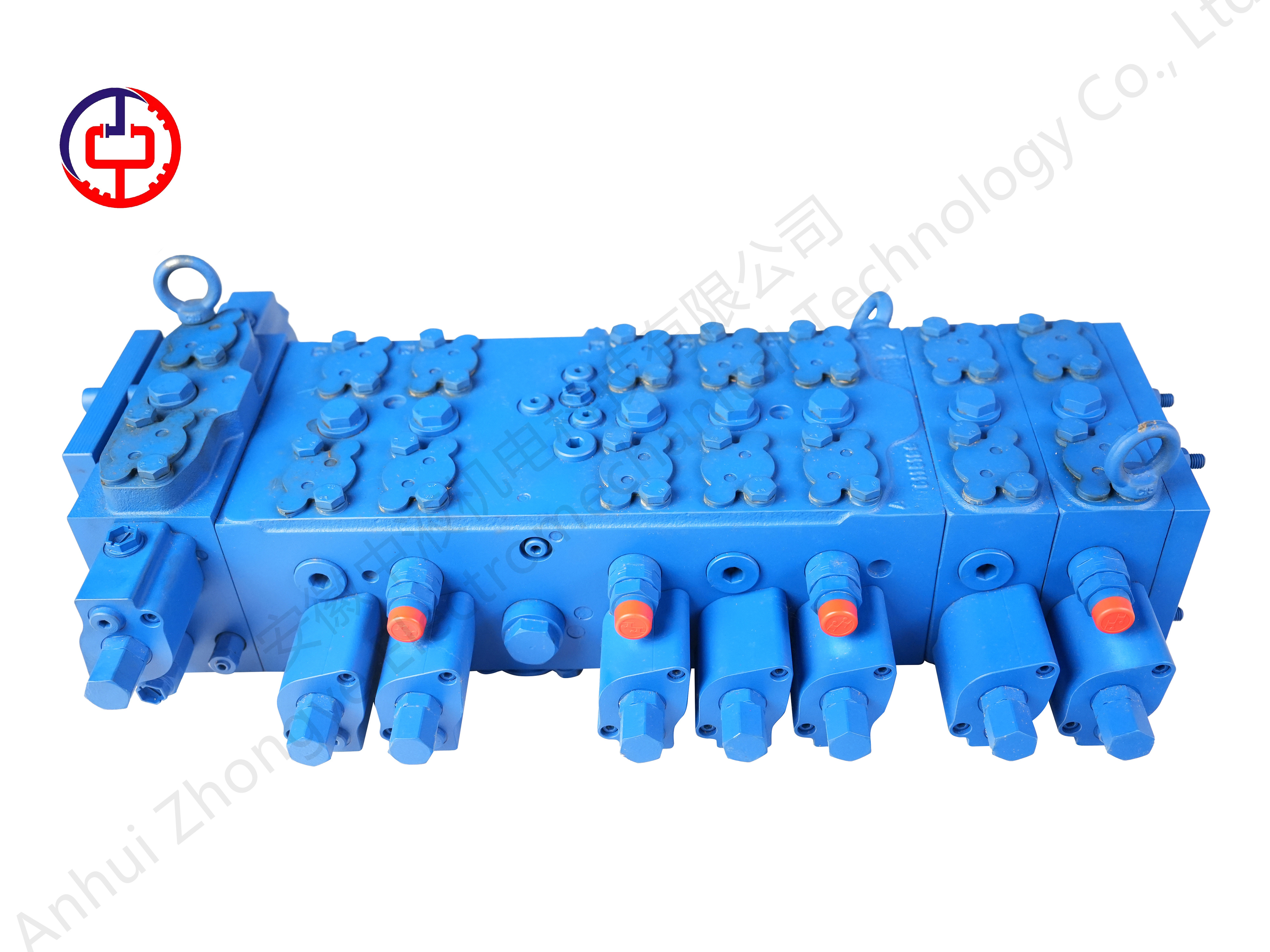

(1) The hydraulic pump of the excavator distribution valve is mostly a variable piston pump. After working for a period of time, internal parts will inevitably wear and cause internal leakage. The parameters are not coordinated, the flow is insufficient, the oil temperature is too high, the speed is slow and high pressure cannot be established, and the movement is slow and weak. In this case, the hydraulic pump needs to be removed for data measurement to determine the problem, replace the unusable parts or repair the usable parts, reassemble and then debug on The test bench to match the parameters (pressure, flow, power, and variables, etc.) of each circuit.

(2) The important hydraulic component of the excavator distribution valve - the multi-way distribution valve, including the main safety valve, secondary valve, overflow valve, oil replenishment valve, etc. If the pressure set by these valves does not reach the standard pressure, it will also lead to weak work. These valves need to be inspected and adjusted to ensure that their pressure is normal.

Let's always pay attention to the state of the excavator distribution valve, do a good job in maintenance and repair, and make it better serve the engineering construction!

Home

Home

Product

Product

Equipment

Equipment

Contact

Contact