Shake rinsing method: write a certain amount of cleaning test solution into the element and seal the element. Shake the element violently by mechanical means to flush all pollutants inside the element into the test solution, and then measure the contamination of the test solution.

Shake rinsing method is a simple and easy component cleanliness detection method, which is mainly applicable to static components, such as conduits, pipe joints, hoses, filter housings and oil tanks.

The flushing method of the test bench connects the element into the pre purified test bench system, circulates the test solution through the element, flushes all the pollutants inside the element into the test solution, and then collects the sample solution from the system for contamination determination.

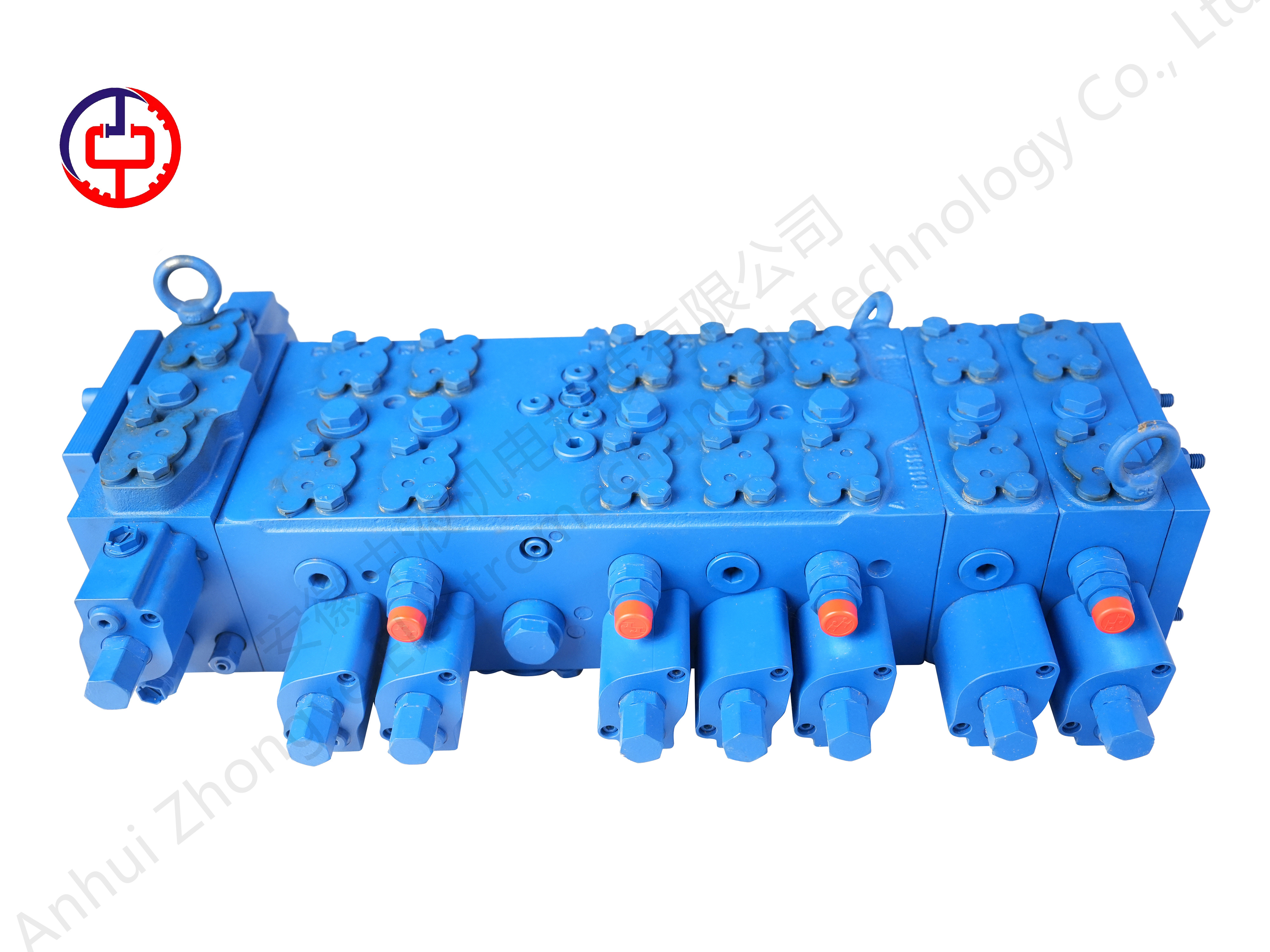

The bench flushing method is mainly used to detect the cleanliness of dynamic components, such as hydraulic oil pump, hydraulic motor, hydraulic cylinder and various hydraulic valve components.

Dismantle the washing method After completely cleaning the exterior of the element, disassemble the element, carefully wash the wet area of the part with detergent, and then collect all solvents and measure their contamination.

In addition, if the cleaning process after component installation is combined with component cleanliness inspection, the component cleanliness can be well controlled and the testing process can be simplified.

Home

Home

Product

Product

Equipment

Equipment

Contact

Contact