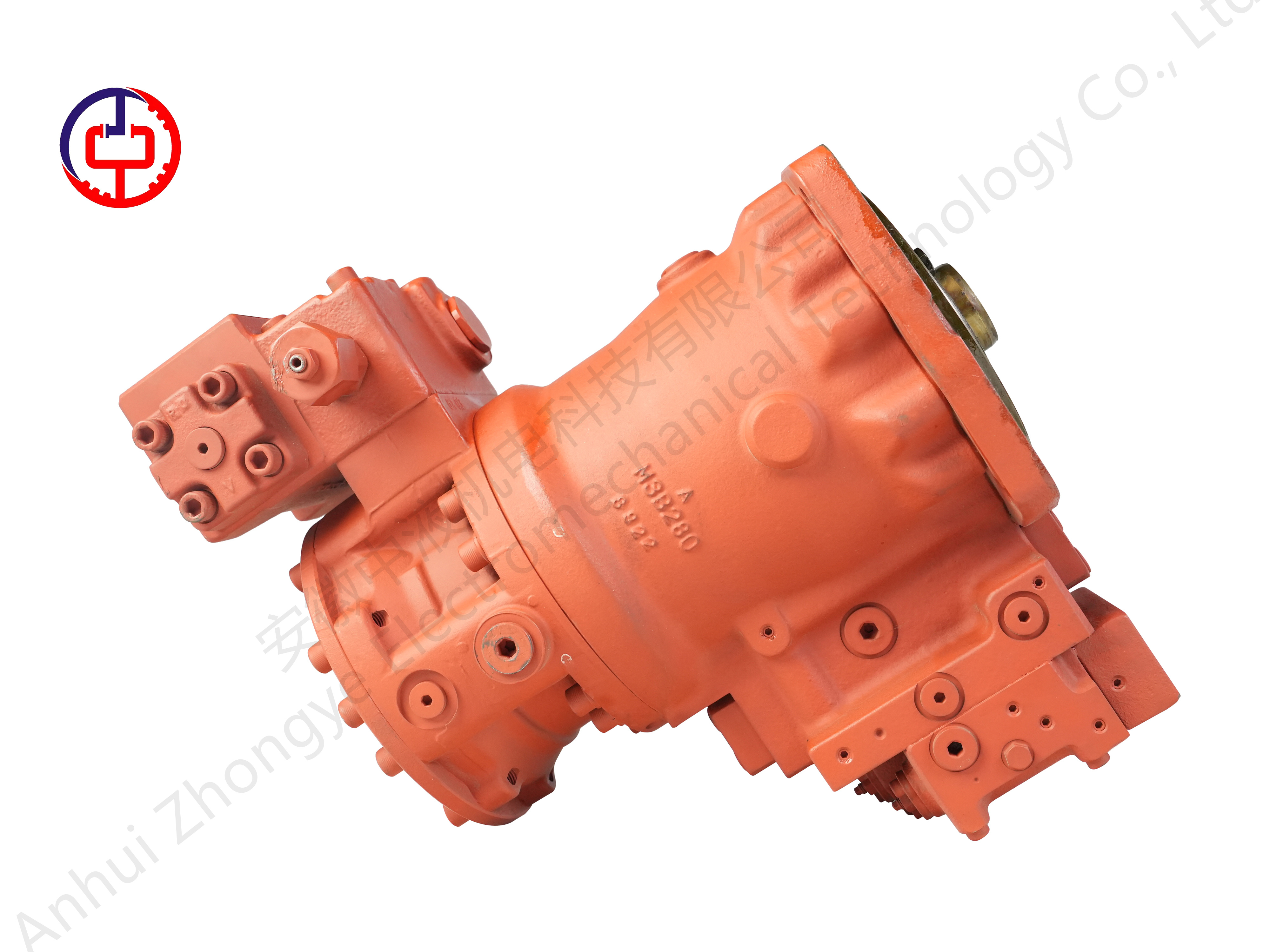

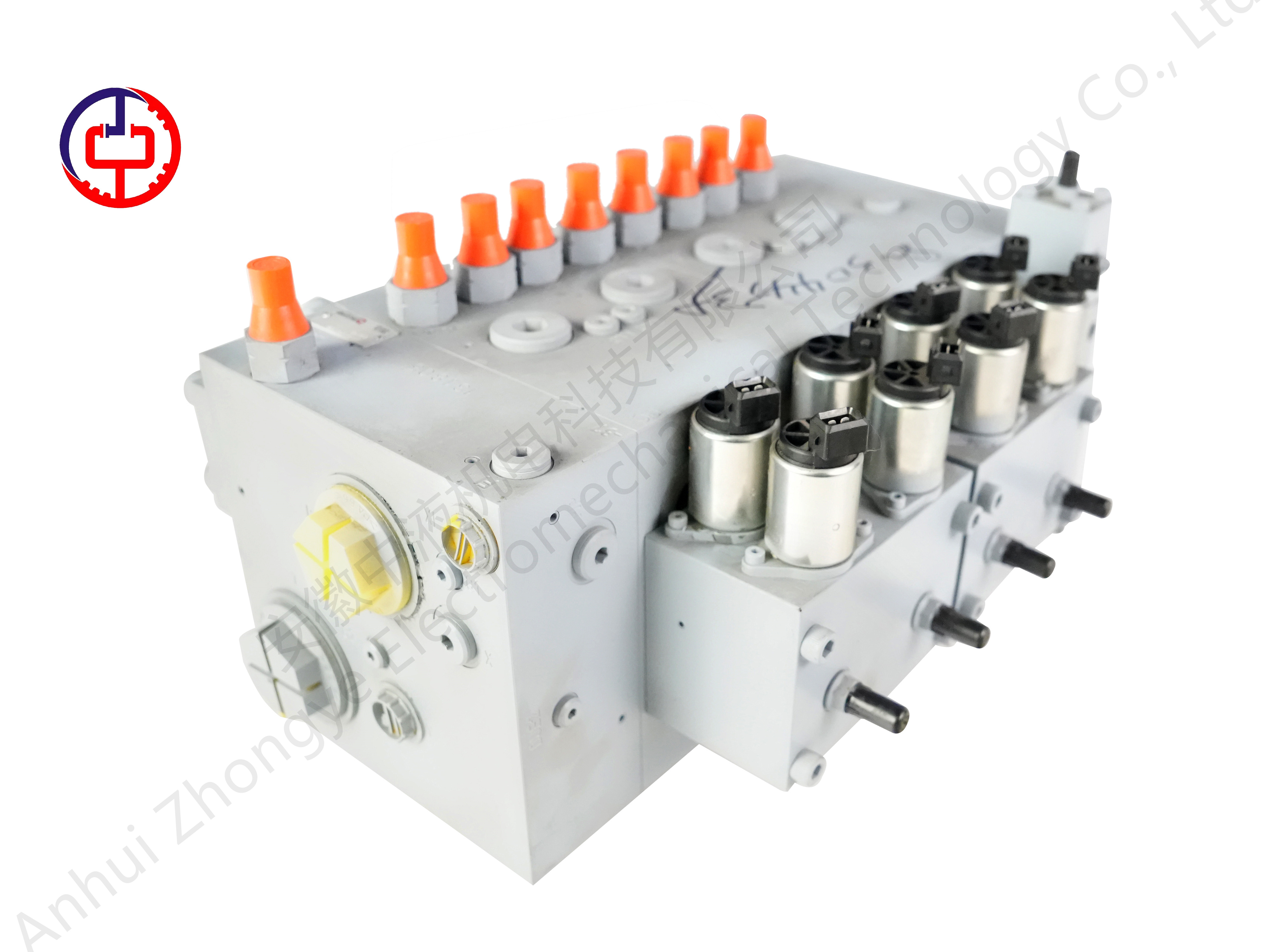

The multi-channel distribution valve of the excavator is an actuator, which is located at the end of the hydraulic transmission to convert the hydraulic energy into mechanical energy to make the platform rotate. This motor adopts a hydraulic motor with axial piston point contact at medium speed.

1. Phenomenon The rotation speed of the platform is lower than 6r/min during operation

2. Cause analysis The structure and working principle of hydraulic motor and axial piston pump are basically the same. The axial piston pump generates power through oil suction and pressure, that is, it converts mechanical energy into liquid pressure energy. The hydraulic motor enters the high pressure oil and discharges the low pressure oil, that is, the liquid pressure energy is converted into mechanical energy. From this point of view, the hydraulic motor is essentially equivalent to the combination of multiple single cylinder piston cylinders, that is, multiple one-way cylinders are evenly distributed in the circumference, and the outer end of the plunger is pushed against the swashplate. When the oil pump supplies pressure oil to the oil cylinder, the plunger extends under the action of the pressure oil and slides down on the swashplate, generating a torque. The oil pump continuously supplies pressure oil to the hydraulic motor, and the hydraulic motor rotates continuously. The final drive gear is meshed with the internal gear ring fixed to the frame through the gear transmission box to drive the platform to rotate. It can be seen from the above that the structure and working principle of the hydraulic motor are basically the same as those of the hydraulic cylinder mentioned above. If the hydraulic motor has a fault of slow rotation speed, its analysis, diagnosis and troubleshooting methods are similar to those of the hydraulic cylinder and axial piston pump of the working device, so I will not repeat them here. Please refer to the above contents for analysis, diagnosis and troubleshooting of hydraulic motor faults.

3. Phenomenon The platform stops and moves when it rotates, that is, the rotation is discontinuous. Slow speed, insufficient strength, etc.

4. Cause analysis The hydraulic motor is an energy conversion device, that is, the input of liquid pressure can convert the output of mechanical energy. If the efficiency of the pressure motor is not considered, the input of energy should be equal to the output. From this point of view, the weak rotation of the hydraulic motor must be the reduction of the energy input to the hydraulic motor. When the energy is difficult to overcome the rotation resistance of the platform, the rotation stops. According to the hydraulic transmission principle, the hydraulic motor rotates by hydraulic pressure. When the control valve is connected to the pressure oil circuit, the hydraulic motor

The stall must be caused by the insufficient working pressure of the oil entering the plunger cylinder of the hydraulic motor to overcome the running resistance of the platform. When the accumulated energy is enough to overcome the resistance, the hydraulic motor will make the hydraulic motor jump and rotate against the resistance, the oil pressure in the system will drop sharply, and the motor will stop, which will form the platform "crawling" repeatedly, or the resistance preventing the hydraulic motor from rotating is too large, causing "crawling".

Home

Home

Product

Product

Equipment

Equipment

Contact

Contact